This article was published in both the print and online versions of Pražská technika Magazine (vol. 5/6/2025; in Czech)

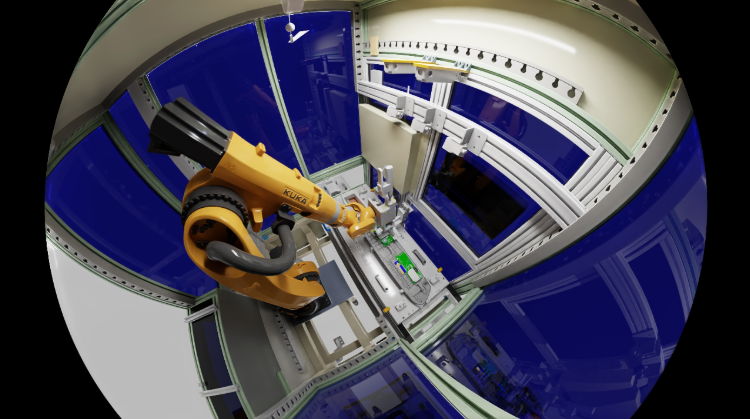

The teams of the RICAIP Testbed Prague at CIIRC CTU, together with the Brandýs nad Labem plant of Continental Automotive – transformed in September 2025 into the new global technology company AUMOVIO – have developed a unique system for creating a digital twin of a production line. For the first time, it enables a fully accurate simulation of the production environment and of camera systems functioning in connection with control logic and artificial intelligence. The solution utilises the NVIDIA Omniverse platform, delivering a breakthrough in virtual commissioning that shortens the ramp-up phase of new production, increases reliability, and paves the way for full digital integration of manufacturing technologies. The collaboration is closely linked to the RAASCEMAN project, in which both organisations are involved.

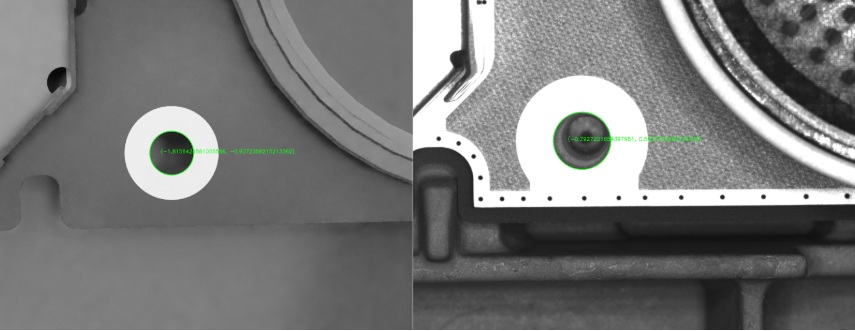

Industrial companies face pressure to accelerate production, increase precision, and simultaneously seek new tools for digitalisation and standardisation. In reality, manufacturing processes are often more complex. Each component may have slight deviations, complicating automation. This is critical, for example, in automatic screw-driving, where even a millimetre deviation can lead to a non-compliant joint. Camera systems therefore play a key role, particularly in determining the exact position of components.

“Because we were among the first to start working with NVIDIA Omniverse back in 2022, we now have the know-how that we can offer to industry and further develop together with our partners. Virtual commissioning of production lines is a trend that will become the norm.”

Ondřej Švec, RICAIP Testbed Prague team at CIIRC CTU

One of the biggest challenges is synchronising robotic cells with camera systems so that these systems can be configured before being deployed in real operation. The new solution developed through the collaboration of CIIRC CTU, RICAIP, and Continental Automotive/ AUMOVIO enables camera systems used in manufacturing to be configured and tested entirely in a virtual environment – even before the real production line is built. The result is not only a model but an intelligent digital testing workstation that autonomously generates different manufacturing scenarios and prepares the system for real-world operation with maximum accuracy.

“Collaboration with the RICAIP Testbed Prague and CIIRC CTU helps us define standards for future production lines. Thanks to the digital twin, we have certainty that what we receive from suppliers meets our requirements,” says Adam Tomášek of AUMOVIO.

A Digital Twin as the Future Standard of Manufacturing

The newly developed software framework integrates the simulation of camera systems with digital twins in the NVIDIA Omniverse environment. It creates and manages a realistic digital environment where actual production conditions, random object positions, or slight manufacturing deviations can be simulated. Algorithms for camera systems can be tested in a safe virtual space, AI learning loops can be generated without the need for real data, and the simulations can be connected to PLCs, HMIs, and other elements of the digital twin. The system builds on a real robotic cell from AUMOVIO’s production, for which a simulation model and algorithms were developed. These now serve as a reference digital twin for new production lines as well.

“The uniqueness of the solution lies in the integration of camera systems and their simulation in a 3D environment fully connected to the industrial ecosystem. Thanks to the mastery of co-simulations and high precision, including the development and testing of AI models directly within the digital twin, the technology of virtual commissioning has been pushed to a new level – not only in the Czech Republic but across Europe.”

Tomáš Jochman, RICAIP Testbed Prague at CIIRC CTU

The system has already demonstrated concrete benefits: it shortens the ramp-up time of new production lines, increases quality thanks to pre-optimised parameters, and reduces costs, as most testing and tuning can be performed without real manufacturing. The simulation of scenarios increases the reliability of camera systems and enables operator training before real operation begins.

Researchers from CIIRC CTU and experts from AUMOVIO are planning further development of the system toward simulations of more complex manufacturing tasks, such as robotic adhesive application, 6D pose estimation for bin picking, and integration with CFD or FEA simulations. The digital twin is thus becoming not only a tool for designing production but also for predictive control, maintenance, and further innovation.