Based on this article, originally prepared and published by the National Centre for Industry 4.0.

On 20 November 2025, the National Centre for Industry 4.0 organised a meeting of the Czech Automotive Industry Association – AutoSAP – Supplier Division, hosted at the RICAIP Testbed Prague at the Czech Institute of Informatics, Robotics and Cybernetics, Czech Technical University in Prague (CIIRC CTU). More than forty representatives of companies, research organisations, and AutoSAP partners took part in the event. Members of the RAASCEMAN team from AUMOVIO and the RICAIP Testbed Prague presented the RAASCEMAN project and a digital twin of a production line with integrated AI and camera systems as a result of joint collaboration.

The main aim of the event was to discuss the current challenges facing the automotive industry, introduce specific technological solutions to boost production efficiency and strengthen supply chains, and highlight successful collaborations between industry and academia.

The programme opened with an introductory AutoSAP session focused on the current state of vehicle production and sales, as well as related topics influencing the automotive sector. This was followed by a specialist block on efficient supply chain and network management using AI, led by Deloitte CE experts Jan Hejtmánek and Lukáš Jílek. They presented modern approaches to automating procurement processes, working with inventory data, and implementing connected real-time planning – all of which help companies enhance their flexibility and resilience.

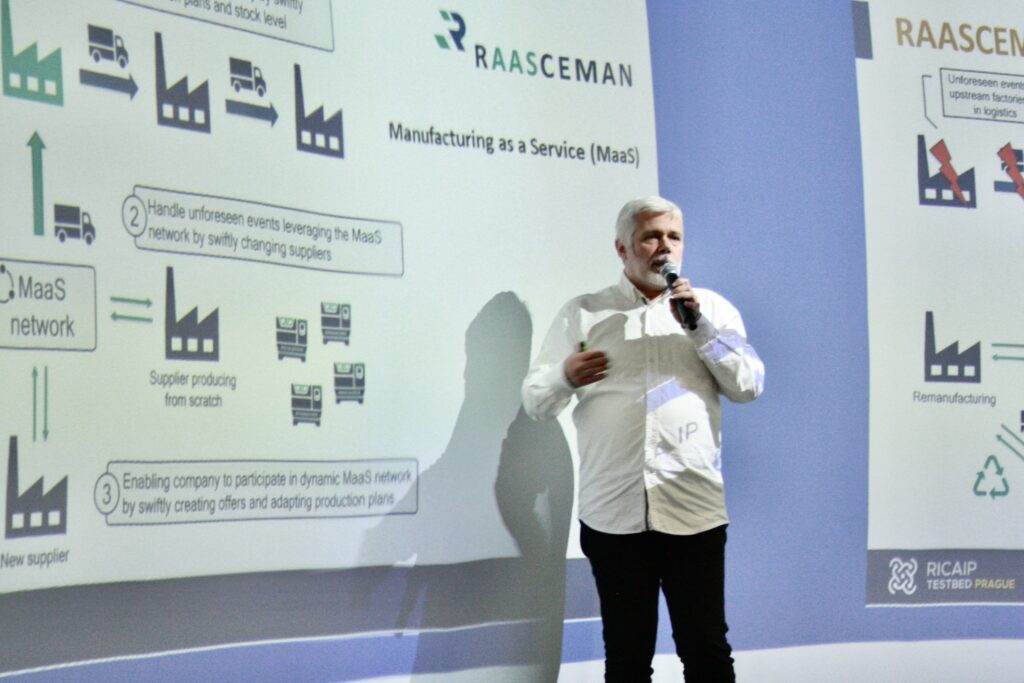

A major highlight of the event was the presentation of the collaboration between AUMOVIO CZ and the RICAIP Testbed Prague, delivered by Pavel Burget (CIIRC CTU) and Jakub Hamerník (AUMOVIO). They demonstrated how this cooperation contributed to the digitalisation of the company’s plant in Brandýs nad Labem, helping it become part of the Global Lighthouse Network of world-leading manufacturers. They also presented the use of a digital twin of the production line in the NVIDIA Omniverse environment and follow-up activities within the RAASCEMAN project, which focuses on building resilient and adaptable supply chains.

Petr Kolář from RCMT, Faculty of Mechanical Engineering at CTU, followed with examples of improving machining efficiency with added benefits in energy savings and ESG performance. He also addressed the issue of workforce shortages through production automation, opportunities to test automation and robotic applications in the RICAIP Testbed at CTU, and the funding options available for companies collaborating with CTU research teams.

Researchers from CIIRC CTU – Přemysl Šůcha and Michal Sojka – then took the floor. They shared concrete examples showing how well-executed data integration and the deployment of optimisation algorithms have helped various types of manufacturing companies achieve significant savings, increase production flexibility, and reduce energy consumption.

The event concluded with guided tours of both floors of the RICAIP Testbed Prague and selected CIIRC CTU laboratories. Participants visited, among others, the IMR (Intelligent and Mobile Robotics) laboratory led by Libor Přeučil’s team, where they learned about research in autonomous and vision-based robot navigation, logistics system optimisation, and intelligent object manipulation. Successful examples of transferring these technologies into industrial practice were also showcased.

Participants were also impressed by a demonstration from the ROP (Robotic Perception Group) led by Karla Štěpánová, which focuses on intuitive human-robot collaboration. The team presented technologies enabling robots to learn from demonstrations, interpret human gestures and visual cues, and make multimodal decisions — allowing robots to adapt quickly to new tasks without complex programming.

The meeting highlighted the essential role of close cooperation between industry, research, and technology centres in building flexible and competitive manufacturing in a time of rapid transformation in the automotive sector. The meeting also supported the objectives of the RAASCEMAN project by connecting industrial and research partners and enabling the sharing of experiences with the implementation of modern digital and automation solutions in manufacturing companies.